Problem statement

SMEs in Montenegro and beyond face mounting challenges in balancing sustainability and innovation. A significant issue is the vast accumulation of plastic waste, particularly PET bottles, which contributes to environmental degradation and strains local ecosystems. Concurrently, there is rising demand for cost-effective, customizable, and eco-friendly products in manufacturing industries. 3D Soba tackled these challenges by pioneering the recycling of PET plastic bottles into high-quality filament for 3D printing. This innovative approach transformed waste into opportunity, enabling the creation of durable, customizable products like furniture, tools, and artistic decor while drastically reducing plastic pollution. By integrating recycling processes with advanced 3D manufacturing technologies, 3D Soba optimized material resource usage, cut production costs, and demonstrated the tangible benefits of the circular economy. Furthermore, they expanded their impact through education and training programs, empowering SMEs, individuals, and local communities to adopt sustainable practices and 3D printing solutions, fostering long-term innovation and environmental responsibility.

Main outcome

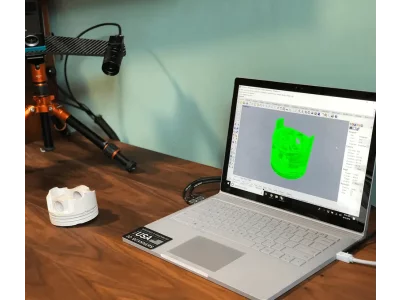

The implementation of recycled PET plastic in 3D printing processes delivered transformative outcomes for sustainable manufacturing. 3D Soba successfully reduced plastic waste by transforming it into high-quality 3D filament, contributing to a cleaner environment and circular economy goals. SMEs benefited from affordable, customizable products, including furniture, tools, and unique designs. Production costs were reduced, and material efficiency improved, showcasing innovation in eco-friendly manufacturing. Additionally, educational efforts empowered businesses and individuals to adopt 3D technologies, fostering local creativity and sustainable practices.

Concrete examples of 3D Soba's collaborations include:

1. Partnership with MFC: 3D Soba cooperated with MFC to develop various 3D printed products that significantly contributed to MFC's brand awareness. One notable example is the creation of a custom-designed trophy for the event winner, showcasing the versatility and quality of recycled PET filament in promotional items.

2. Collaboration with ICT Cortex: In collaboration with ICT Cortex, 3D Soba designed and produced a 3D printed PERPER, a symbolic item used for branding and awareness initiatives. This project highlighted the creative potential of 3D printing technology in enhancing corporate identity and promotional strategies.