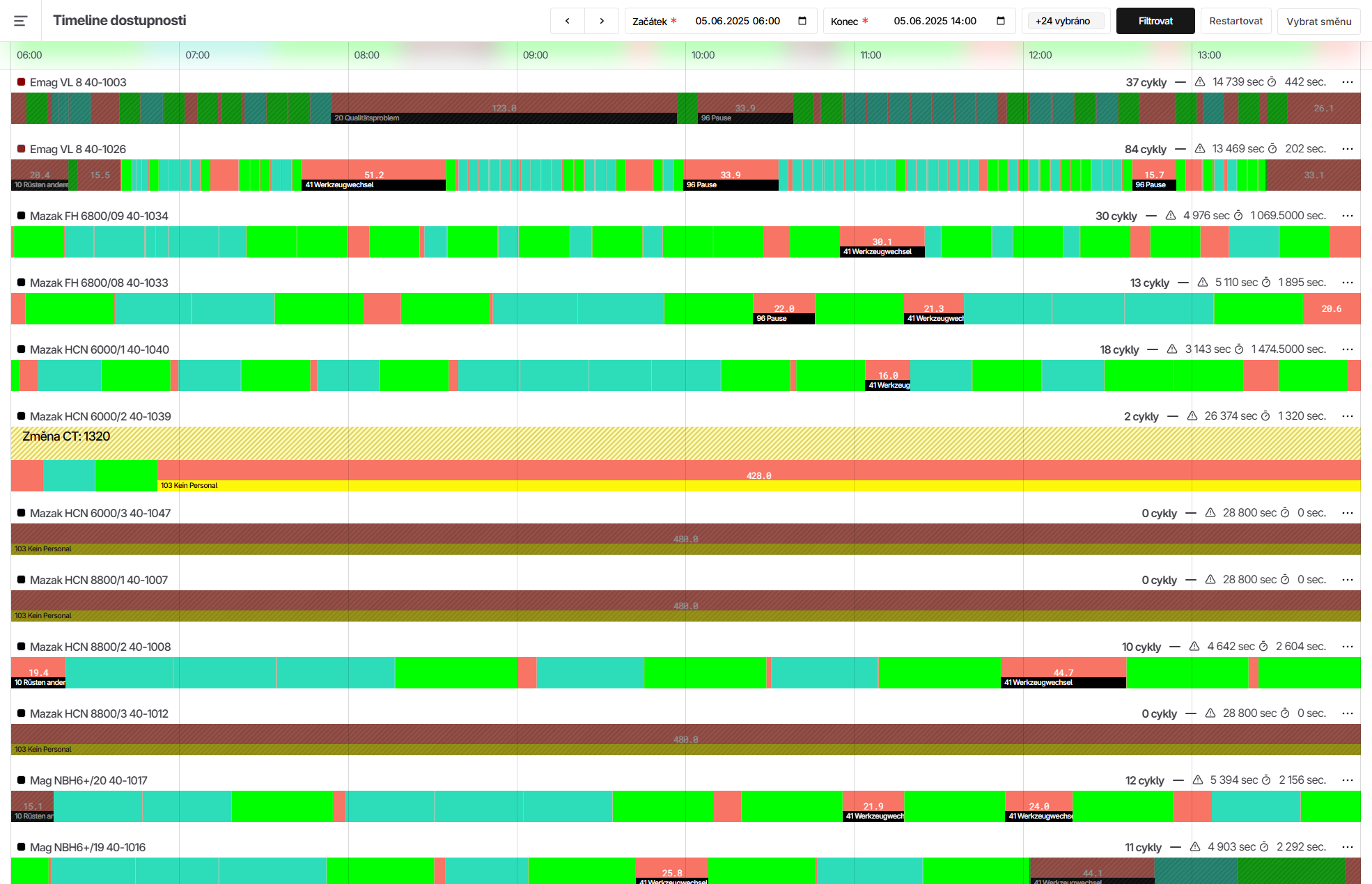

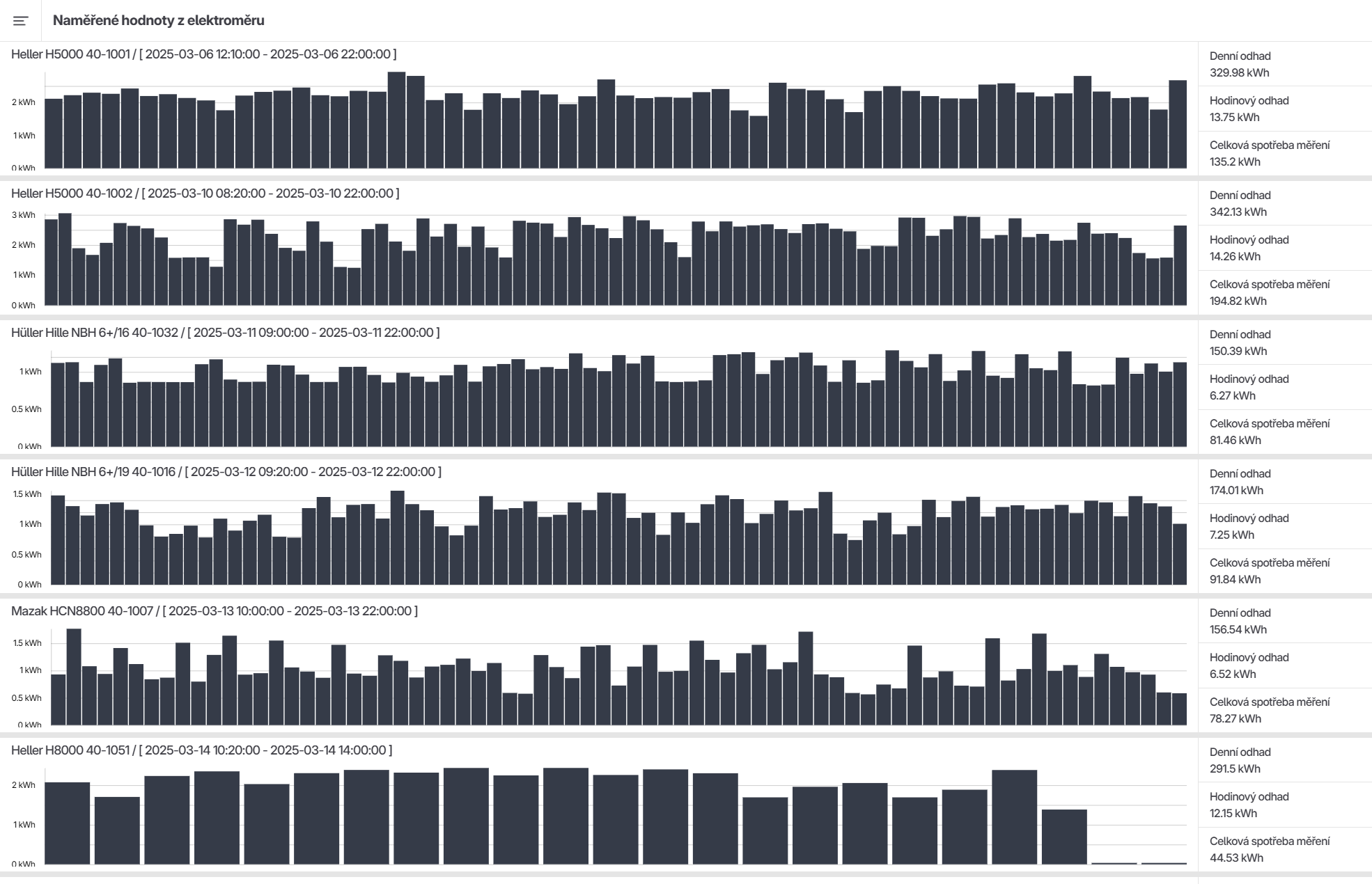

Problem statement

This is a method of collecting production data. For example, which machines are working, which are idle, how long individual operations take, or where unnecessary downtime occurs. The data is automatically collected by our equipment. You can view the information in a clear format in our web application. As a result, management and employees have a clear picture of production and can respond quickly to problems, increase efficiency, and reduce costs.

Main outcome

We increase the efficiency of manufacturing companies by tens of percent at minimal cost. Our successful projects speak for themselves. Beinbauer Automotive CZ increased its production efficiency by 10% in one year. Crystalex CZ, the largest Czech glassworks for the production of utility glass, increased its efficiency by 5% within the first few weeks. The implementation took place without stopping production and without interfering with the IT infrastructure.We increase the efficiency of manufacturing companies by tens of percent at minimal cost. Our successful projects speak for themselves. Beinbauer Automotive CZ increased its production efficiency by 10% in one year. Crystalex CZ, the largest Czech glassworks for the production of utility glass, increased its efficiency by 5% within the first few weeks. The implementation took place without stopping production and without interfering with the IT infrastructure.